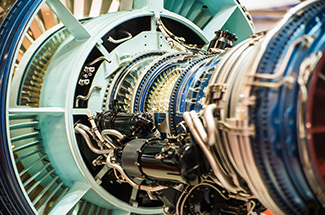

Compression Molding

Compression molding of composites accommodates a wide variety of resin and reinforcement combinations. The process yields net shape components, and can easily allow for varying cross sections, complex geometries and an array of “molded in” features such as metal inserts, ribs and bosses.

Our compression molding work cells are purpose built, automated and have integrated capabilities specific to composites processing. Precision controls continuously monitor and ensure exact temperature, pressure and dwell curves. Our smart presses are integrated with purpose-built production tooling allowing the mold to interface with the press ensuring time, temperature and pressure profiles which exactly match process specification resulting in high outputs of compliant products.