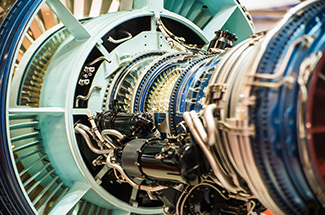

Resin Transfer Molding Capabilities

Our Resin Transfer Molding (RTM) process brings together high-performance resin systems with braided carbon fiber, kevlar and other reinforcement materials which produce high performance composite products with superior strength, stiffness, toughness and damage tolerance. In addition, our RTM components offer dramatic reductions in weight and a high degree of cost efficiency.

We offer customized braided reinforcements which are available in a variety of product forms including preforms, sleeves, broad forms, tapes and unidirectional material with biaxial or triaxial customized architectures. Braided reinforcement configurations provide for uniform, repeatable orientations in even the most complex of geometries.

Our RTM work cells incorporate sophisticated resin injection systems and purpose-built work cell flow lines which are state of the art ensuring complete control of processing parameters and data management for the highest degrees of process automation, data logging and process predictability/repeatability.